Collections

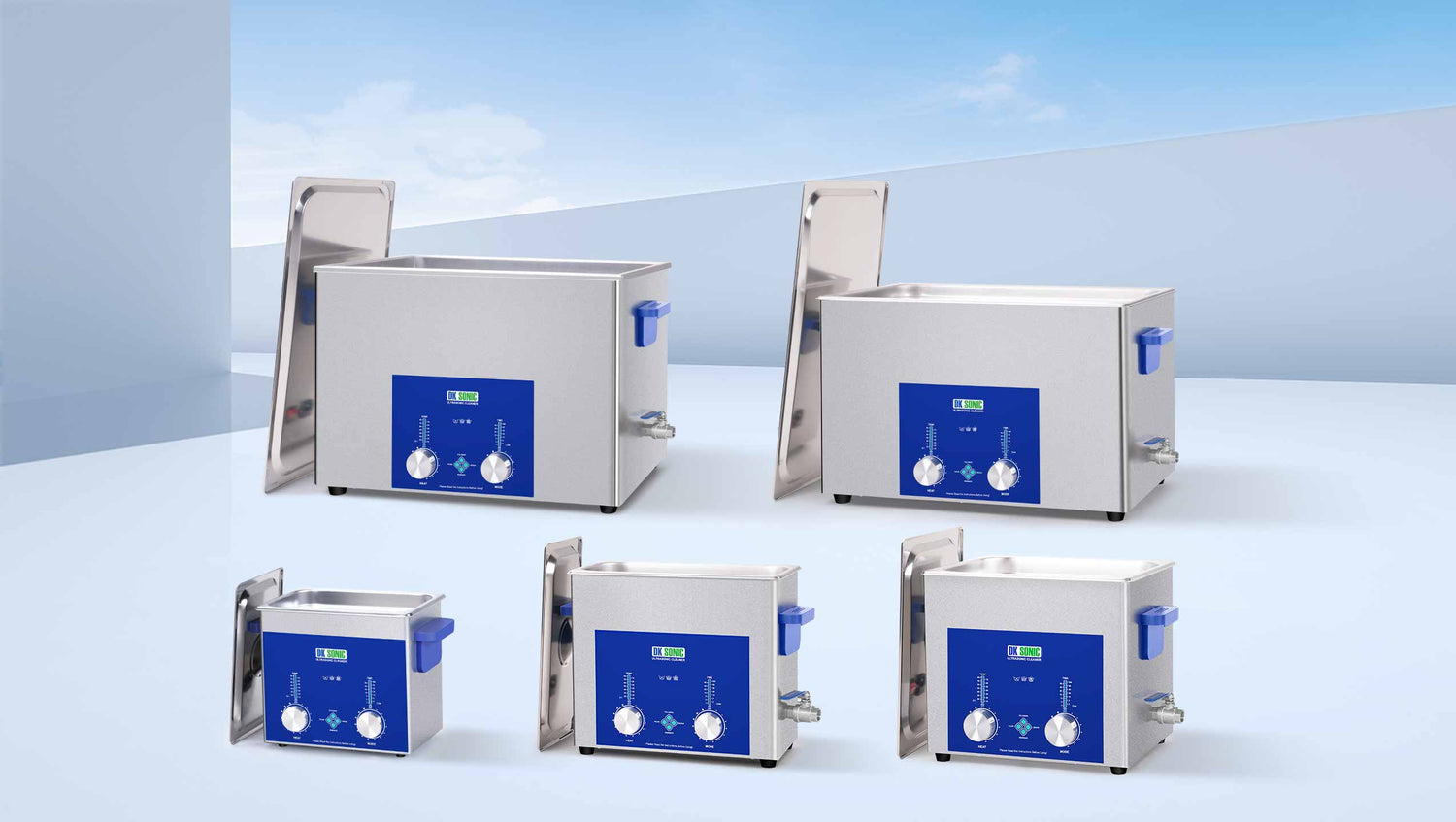

Featured Products

-

Sold out

DK SONIC 37L Ultrasonic Cleaner, Touch Control Sonic Carburetor Cleaner

Regular price $5,068.00Regular price -

Sold out

DK SONIC 37L Ultrasonic Cleaner, Digital Sonic Carburetor Cleaner

Regular price $4,210.00Regular price -

Sold out

DK SONIC 37L Ultrasonic Cleaner, Encoded Sonic Carburetor Cleaner

Regular price $4,678.00Regular price -

Sold out

DK SONIC 30L Ultrasonic Cleaner, Mechanical Sonic Carburetor, Gun Cleaner

Regular price $8,576.00Regular price

Promotion

Promotional Items

-

Sold out

Vendor:DK SONIC

Vendor:DK SONICDK SONIC 3L Ultrasonic Cleaner, Encoded Sonic Jewelry Cleaner

Regular price $1,014.00Regular price -

Sold out

Vendor:DK SONIC

Vendor:DK SONICDK SONIC 400ml Ultrasonic Cleaner, Sonic Jewelry Eyeglasses Cleaner

Regular price $250.00Regular price

1

2

3

4

5

What Clients Say?

DK SONIC News

Have A Question?

Common Questions

Does an ultrasonic cleaner need to be added with cleaning agent?

Does an ultrasonic cleaner need to be added with cleaning agent?

Although ultrasonic cleaning machines are very powerful in physical cleaning, for most practical applications, especially when it comes to grease and stubborn stains, the use of special cleaning agents is a necessary means to achieve the best cleaning effect, improve efficiency, and protect the objects being cleaned. Using only water is usually only suitable for very simple cleaning tasks or specific rinsing steps.

How to choose the operating frequency of ultrasonic cleaning machine?

How to choose the operating frequency of ultrasonic cleaning machine?

Low-frequency ultrasonic waves (20kHz - 40kHz): Cavitation bubbles are larger, release more energy when they burst, and have a violent impact. Suitable for removing heavy dirt (such as oil stains, metal debris). However, it may cause surface damage (such as micro-dents) to precision parts or soft materials (such as aluminum, copper, and plastic).

High-frequency ultrasonic waves (40kHz - 100kHz+): Cavitation bubbles are denser and smaller, with more uniform energy distribution and stronger penetration. Suitable for cleaning complex structures (blind holes, gaps) and precision objects (electronic components, optical lenses). Safer for fragile materials, but weaker in removing heavy dirt.

What is the optimal operating temperature range for ultrasonic cleaning machines?

What is the optimal operating temperature range for ultrasonic cleaning machines?

Water-based cleaning fluid: This is the most commonly used. For most water-based cleaning agents, the optimal temperature range is usually between 50°C and 60°C. In this temperature range, the viscosity of dirt (especially grease and oil) decreases, making it easier to peel and emulsify. The cavitation effect of ultrasound is more efficient at this temperature (the cavitation intensity is weak when the temperature is too low, and the cavitation intensity is also weakened when the temperature is too high because the internal pressure of the bubbles decreases).

Advantages of ultrasonic cleaning compared to traditional cleaning

Advantages of ultrasonic cleaning compared to traditional cleaning

Higher cleanliness and better effect: The core advantage of ultrasound lies in the "cavitation effect" it produces. When high-frequency sound waves propagate in liquids, countless tiny vacuum bubbles (cavitation bubbles) are generated. These bubbles release huge local energy (high temperature and high pressure shock waves) when they collapse (implosion) in an instant, which can strongly peel off stubborn dirt attached to the surface of the object, and even stains inside micron-level gaps, holes, grooves, and blind holes can be effectively removed. Cleaning without dead angles: Sound waves can propagate evenly in liquids. As long as the workpiece is immersed in the cleaning liquid, all its surfaces (including complex geometric shapes, deep holes, slits, threads and other parts that are difficult to reach manually) can be affected by ultrasound, achieving true all-round and dead angle-free cleaning.

Scope of use of ultrasonic cleaning machine

Scope of use of ultrasonic cleaning machine

Wider scope of application: It can clean workpieces of various materials (metal, plastic, ceramic, glass, silicon wafer, etc.) and various shapes (complex, precise, tiny). It is widely used in electronics, optics, medical treatment, jewelry, watches, automobiles, aviation, machinery manufacturing, laboratories, printing, electroplating pre-treatment and many other industries.

Which products are not suitable for cleaning with an ultrasonic cleaner?

Which products are not suitable for cleaning with an ultrasonic cleaner?

The following products are not suitable for ultrasonic cleaning:

Soft materials: Surfaces can be damaged by cavitation (soft metals, polished surfaces).

Surface coatings/treatments: Can be peeled off (paint, plating, non-stick coatings, printing).

Porous/fragile structures: Can absorb liquids or break internally (organic gemstones, fractured gemstones, soft plastics).

Precise/complex structures: Vibrations can interfere with or damage (movements, electronic components).

Bonded structures: Vibrations can weaken adhesives (antiques, restorations, loose gemstones).

Will ultrasonic cleaning cause environmental pollution when cleaning items?

Will ultrasonic cleaning cause environmental pollution when cleaning items?

Operating principle itself (physical process): Ultrasonic cleaning mainly relies on high-frequency sound waves to produce a "cavitation effect" in the liquid, that is, the formation, growth and violent collapse of tiny bubbles, thereby generating a strong impact force and micro-jet to peel off the dirt on the surface of the object. This physical process itself does not produce harmful chemicals, nor does it deplete the ozone layer, and will not directly pollute the air, water or soil.

What is the role of the heating function of an ultrasonic cleaning machine?

What is the role of the heating function of an ultrasonic cleaning machine?

Enhanced cleaning effect (core function):

Reducing liquid surface tension: Heating the cleaning liquid reduces its surface tension. The lower the surface tension, the easier it is for ultrasound to produce cavitation in the liquid (the process of forming and breaking tiny bubbles), resulting in more bubbles with greater energy. Stronger cavitation means stronger shock waves and microjets, which significantly improves the ability to remove stubborn dirt (especially grease, oil, wax, polishing paste, etc.). Most cleaning agents (especially degreasers) react faster and more actively at higher temperatures. Heat helps break down grease and emulsify oil, making it easier for cleaning agent molecules to penetrate and dissolve stains, working in synergy with the cavitation effect of ultrasound to double the effect. Due to the enhancement of the above effects, heating can significantly shorten the time required to achieve the desired cleaning effect and improve cleaning efficiency.

How to choose the size of a household ultrasonic cleaner

How to choose the size of a household ultrasonic cleaner

Core principles for choosing the size

Match the volume of the item: The length/width of the cleaning tank must be 1.5 times greater than the maximum size of the item to ensure uniform coverage of the sound waves.

Reserve liquid space: The water level must completely submerge the item and leave at least 2cm of height

Taking into account storage convenience: The mini type can be placed in a cabinet or desktop corner, and the medium type requires countertop space

Balance between power and efficiency: Small capacity (≤600ml) with 30-50W power is sufficient;

Large capacity (≥5L) requires more than 100W power to ensure cleaning power

Ultrasonic cleaning machine warranty policy

Ultrasonic cleaning machine warranty policy

The warranty period is 1 year. During this period, if you find any damage to the machine, you can contact us at any time. If the machine can be repaired, we will provide you with corresponding repair services based on the suggestions given by the engineer. If it cannot be repaired, we will provide you with a replacement or refund service based on your needs.